We make big shapes.

Quick and easy.

We can build that!

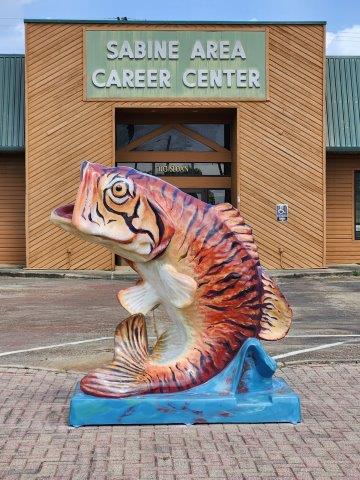

Wonky shapes, square shapes, we’ve made them all. Our crew loves shipping out eye-catching beauties, molds with a super smooth finish, and anything else that’s satisfying to make.

We partner with a strong network of material suppliers, painters, studios, and prop shops to get you what you need.

If it’s a big shape, we can make it happen!

Big Shapes Fast

We’re the best tool in your toolbox. Our process is quick and easy, gives you a useful quality piece, and keeps you moving on the rest of your project.

You need fast quotes and simple answers.

This is where you get them.

Big shapes. Global companies.

Made right, or we’ll make it right.

Our process is quick and proven to deliver, project after project. If something’s not right when it shows up, we’ll work with you to correct it.

We help you make displays people will love.

Whatever it is, we’ve probably already made one, and can make yours the same way.

Outshaped brings your brand, art, sculptures, tradeshow designs to life with LARGE, 3D shapes. Bring the WOW to your next tradeshow, golf outing or art exhibit with custom 3D molds or art pieces or 3D letters. We manufacture your piece with Expanded Polystyrene Foam, Fiberglass, MDF or High-Density Urethane Foam based on your use and the durability needed for your final product. We can finish your piece so it is ready to go or for some of our artists, we send the final 3D shape raw, so they can do the finishing work on the model.

We are a family-owned business, located in Minnesota, serving customers in the Midwest and across the country. Connect with us today to discuss your next project.

The easy way to make big shapes.